As early as the 1990s, European and American countries began to use low-e reflective glass, and ordinary families later enjoyed government promotion subsidies. Along with the promotion and popularization of domestic concepts of low-carbon, energy conservation and green environmental protection. The low-e reflective glass is be familiar with people because of its energy saving advantages.

But what is Low-E glass?

The concept of low e reflective glass

In physical optics, the relationship between reflection, transmission, and absorption of electromagnetic waves incident on the interface of different media is:

α+ρ +τ =1

α-absorptivity; ρ-reflectance; τ-transmittance

When ρ = τ = 0, α = 1 is called absolute black body;

When α = τ = 0, ρ = 1 is called absolute white body;

When α = ρ = 0, τ = 1 is called a diathermy.

According to Kirchhoff's law of thermal radiation: α = ε. Where ε-emissivity

Assuming that the medium is an opaque surface τ = 0, ε = α = 1-ρ -τ == 1-ρ -0 = 1-ρ.

It can be seen that opaque media with high surface reflectance have low infrared emissivity. The higher the reflectivity, the lower the absorbance,

The lower the emissivity.

In other words, the lower the infrared emissivity, the higher the infrared reflectance.

The same principle applies to glass. Assuming that the glass has a certain light transmission, its own emissivity (absorptivity)

The lower the infrared reflectivity is, the higher it is. This is the origin of low-e coated glass.

In the national standard GB.T 18915.2-2013 coated glass Part 3.2 of the low-emission coated glass is defined as follows:

Low-emissivity coated glass is a type of coated glass that has a high reflectance to infrared rays with a wavelength of 4.5 um to 25um, also known as Low-E

Low emissivity coated glass.

BTG Low-E reflective glass production process

In the industry, from the perspective of manufacturing process, low-e reflective glass has two major categories: online coating and offline coating.

Let's first look at the description of 5.6 emissivity of the national standard GB.T 18915.2-2013: The emissivity of low-emissivity coated glass refers to the hemispherical emissivity of the film surface in the temperature range of 293K and the wavelength of 4.5 um ~ 25um. The emissivity of offline low-emissivity coated glass should be less than 0.15; the emissivity of online low-emissivity coated glass should be less than 0.25.

Judging from the national standard, the emissivity of online reflective glass is higher than offline reflective glass. This means that the low-e reflective glass manufactured by the online coating process is not superior to the offline coating process manufactured in the performance parameters. In fact, the national standard is so defined based on the actual production results.

Let's first look at the difference between online coating and offline coating:

Item | Online coating | Offline coating |

Manufacturing environment | Atmospheric | High vacuum |

Manufacturing method | Chemical spray | Magnetron sputtering |

Substrate material | Glass-high temperature | Glass-normal temperature |

Film material | SnO2 based compounds | Metal Ag-based multilayer composite film |

Film uniformity | Relatively poor uniformity, not suitable for multilayer films | Controllable uniformity of single layer and multi-layer superposition |

Film hardness | Harder, chemical bonding | Harder, binding by adhesion, easy to oxidize |

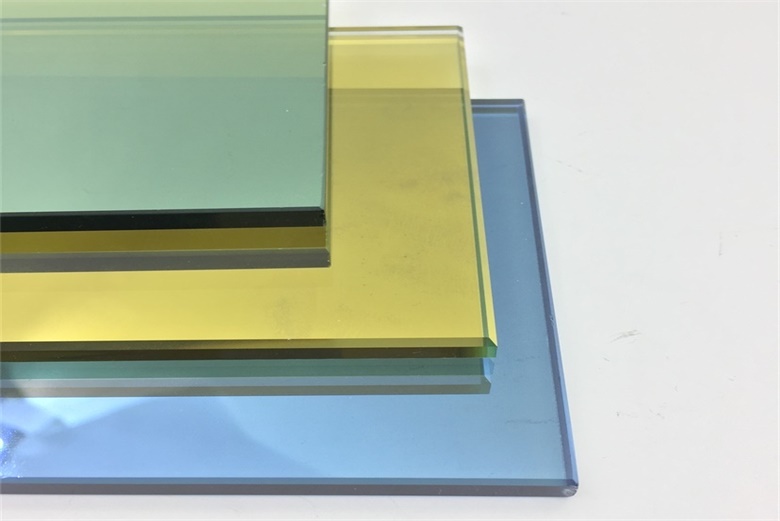

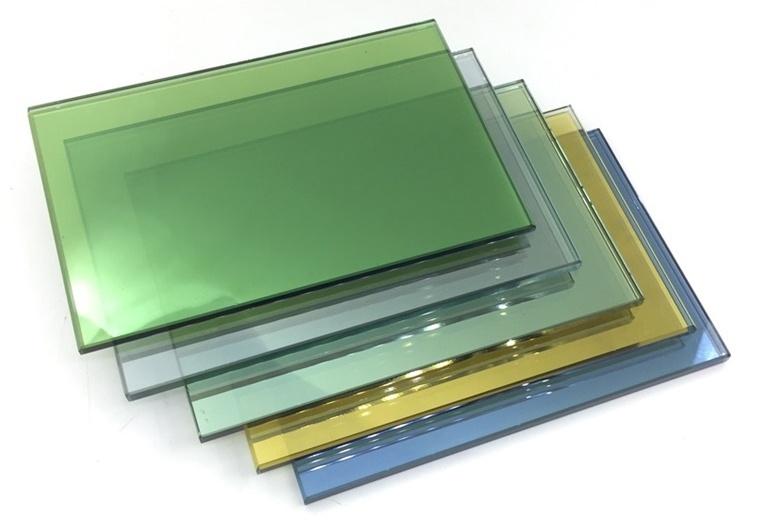

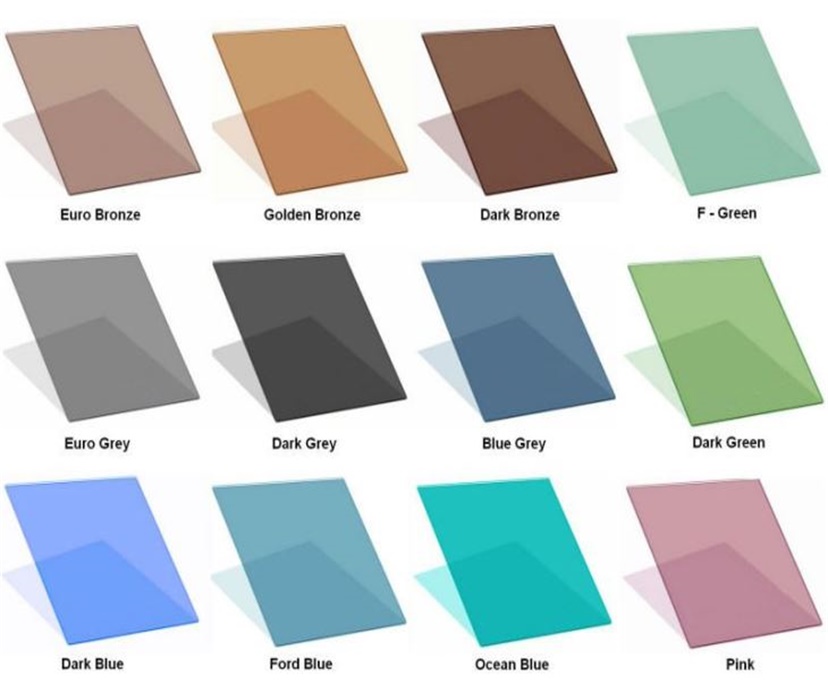

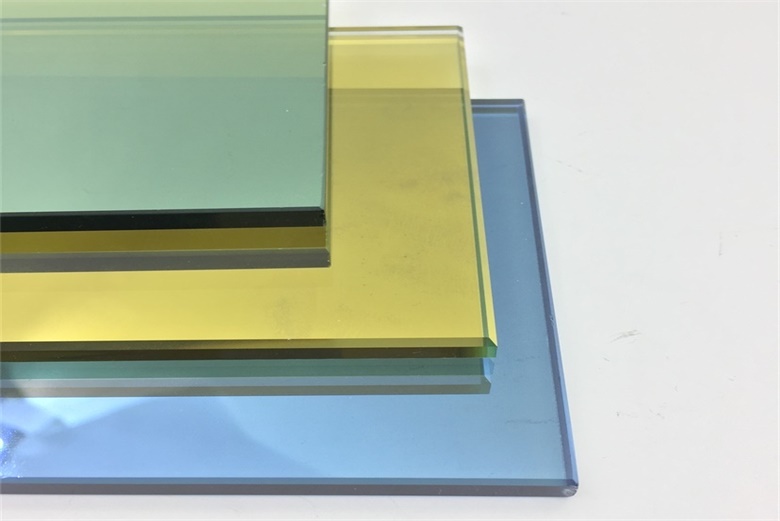

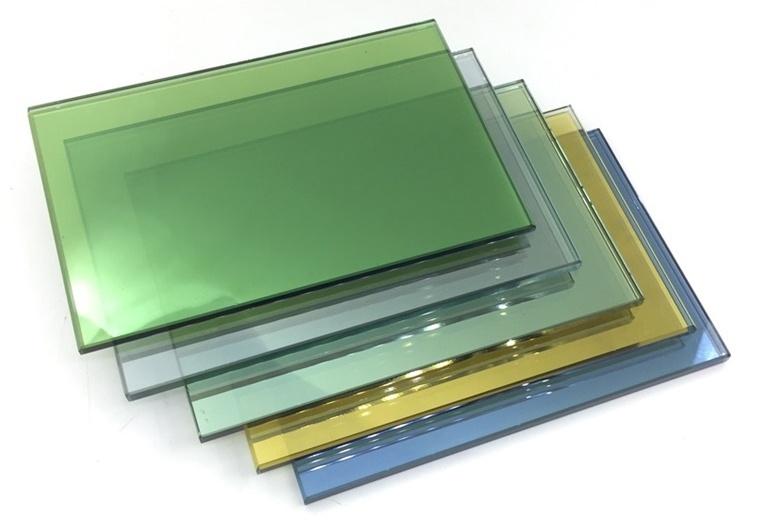

Product Category | Single product, monotonous color | Diversified products and rich colors |

Product stability | Can be used on a single chip | Not single sheet, suitable for insulating glass |

Performance parameter | Relatively poor | Relatively superior |

According to the table, online coating is far from the three silver low-e reflective glass to be talked about. Let's focus on understanding offline coating.It can be simply understood that the on-line coating is a coating on the glass surface during the float glass production process (the beginning of the annealing kiln), and all the processes are completed on the float glass production line; the offline coating is on the float glass. After the glass leaves the factory, secondary processing is completed through a coating machine and other equipment.

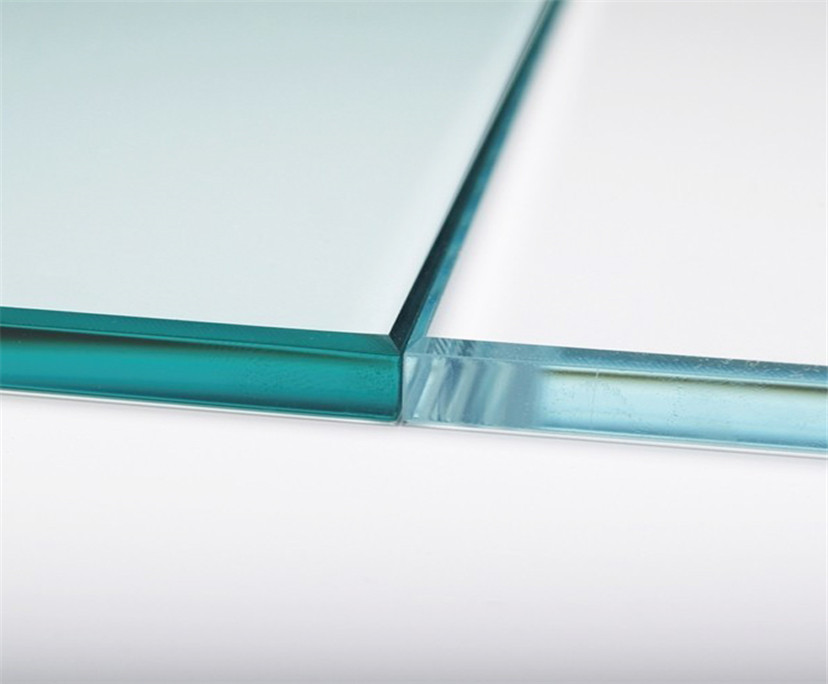

Off-line low-e reflective glass is a vacuum magnetron sputtering method that is coated on the glass surface with a film system containing one, two or three silver layers to better reflect radiant heat and better It can increase the transmittance of visible light and achieve indoor and outdoor light and heat balance, so as to maintain indoor temperature, save the cost of heating and cooling, and achieve the purpose of environmental protection and energy saving; and ensure the comfort of life and work.

The origin and superiority of tri-silver

Generally speaking, a composite film system coated with a silver film on the surface of a glass substrate is called single silver, and a composite film system coated with two silver films is called double silver. The triple silver is a composite film system with three silver layers spaced on the surface of a glass substrate. And it is true in production. However, it does not necessarily mean that the glass coated with three layers of silver film is triple silver, but there is another indicator-light-to-heat ratio.

National standard GB T18091-2015 Light and heat performance of glass curtain wall 3.14, the visible light to solar gain coefficient (visible light to solar gain coefficient) is defined as follows: abbreviation r or LSG, is the material's visible light transmittance and solar energy total transmittance ratio.

The larger the value of the light-to-heat ratio of a product, the better the performance of the product. However, there is currently no officially defined indicator for the distinction between single / double / three silver. We temporarily refer to a data division of a large company in the glass industry:

Glass type | Light to heat ratio LSG |

Reflective glass | LSG>1 |

Single silver glass | 1≤LSG<1.5 |

Double silver glass | 1.5≤LSG<2.0 |

Triple silver glass | 2.0≤LSG<2.4 |

Let's look at a set of offline coating data:

Configuration | Visible light % | Reflective out | Total energy trans (g) | Winter nighttime W/㎡.k | Shading Coefficient | Light to heat ratio LSG |

6 heat reflective monolithic | 64 | 18 | 0.66 | 5.55 | 0.76 | 0.97 |

6 single silver+12A+6 | 66 | 10 | 0.49 | 1.83 | 0.56 | 1.35 |

6 double silver+12A+6 | 67 | 11 | 0.37 | 1.65 | 0.43 | 1.81 |

6 triple silver+12A+6 | 67 | 14 | 0.29 | 1.63 | 0.33 | 2.31 |

From the above data, it can be seen that, while keeping the visible light transmittance close, as the number of silver layers of the film increases, the heat penetration gradually decreases. Compared with single silver and double silver, triple silver Low-E coated glass can maximize the heat balance. Low-emissivity glass, especially the three silver Low-E buildings, can not get heat in the outdoor in summer, but can't get out of the indoor heating in winter. It has superior thermal insulation and excellent "cold winter and cool summer" effect.

In the field of low-emissivity glass, triple silver Low-E coated glass has unparalleled advantages.

www.better-glass.com