The total thickness of the bulletproof glass is proportional to the bulletproof effect. Generally, tempered glass is not allowed, because the broken glass will form dense small particles that affect the observation, and if the tempered glass is broken, the small particles are more likely to fall off, which is not conducive to protect human safety.

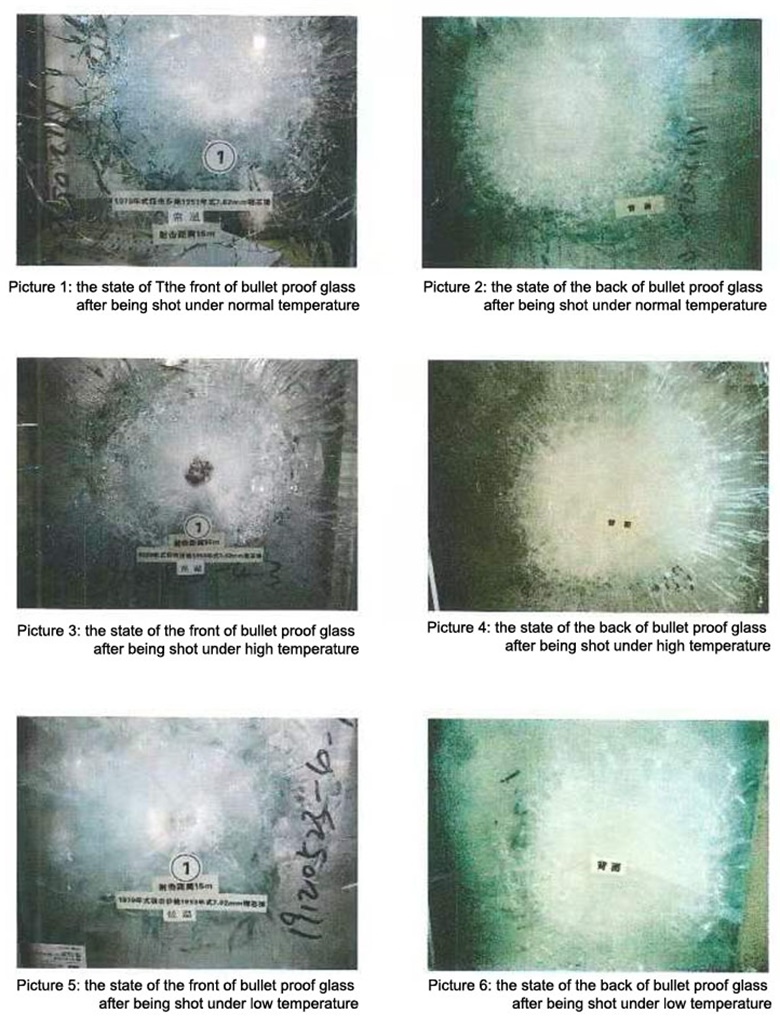

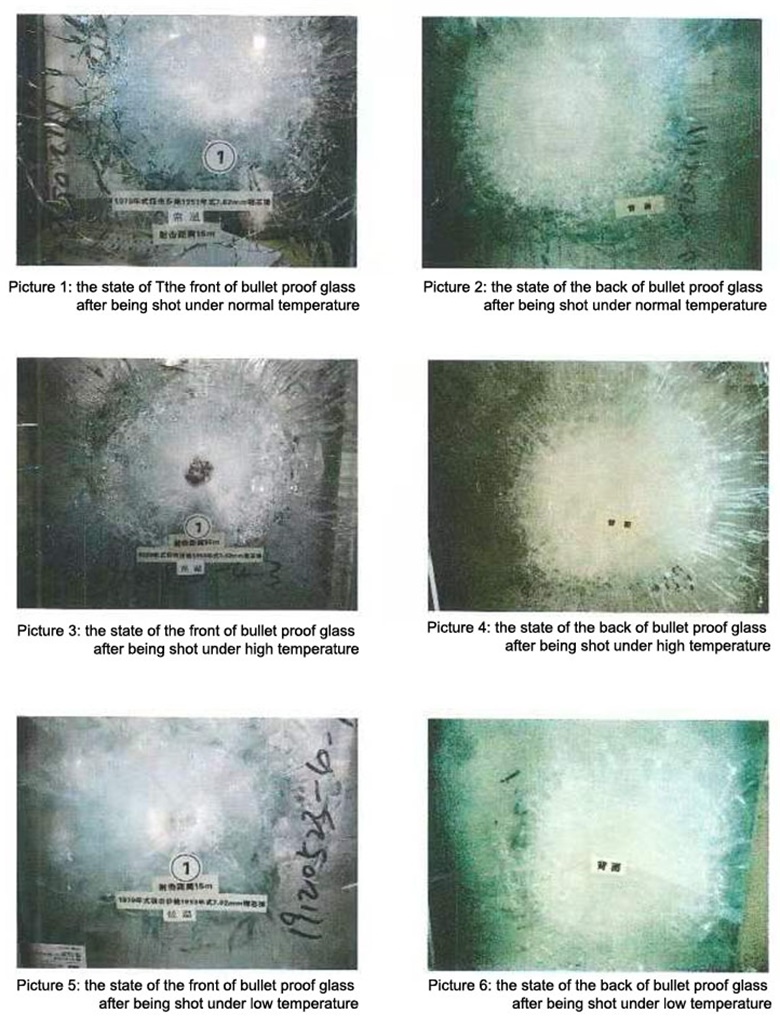

The bullet-proof glass is divided into the front bullet surface (the direction of the bullet hitting) and the back bullet surface. The front bullet faces the shooting direction when installed.

Note: Polycarbonate board also called endurance board, is made of polycarbonate as the main component and co-extrusion technology. The light transmittance of PC board can reach up to 89%, which is comparable to glass; the impact strength is 250-300 times that of ordinary glass, 30 times that of acrylic board of the same thickness, 2-20 times that of tempered glass, and its specific gravity(1.2) is only half for glass. But the PC board is not resistant to strong acid, durability, and alkali, so it needs to be coated with a protective coating.

Bulletproof glass standard

Bulletproof glass standards are divided into national standards and industry standards. The national standard is GB17840-1999. Generally, the domestic implementation of the bulletproof transparent material industry standard GA 165-2016 formulated by the Ministry of Public Security.

According to the GA 165-2016 standard, bulletproof glass is divided into two categories (A and B) 6 grades, as follows:

Classification: After shooting tests on bulletproof transparent material samples, the products are classified as follows according to the state after the test:

| Class A | The bullet or shrapnel did not penetrate the bullet-proof transparent material, and there were splashes on the back of the bullet-proof transparent material, but there was no penetration test card. |

| Class B | The bullet or shrapnel does not penetrate the bulletproof transparent material, and there is no splash on the back of the bulletproof transparent material |

Explanation: Class B is safer and stronger.

Grade: Bulletproof transparent materials are graded according to the ability to resist different firearms and bullets, and are divided into 6 levels:

| Grade | Type of bullet | Warhead mass | Bullet speed m/s | Applicable gun type |

| Grade 1 | 1964-style 7.62mm pistol bullet (lead core) | 4.87g | 330±10 | 1964-style 7.62mm pistol |

| Grade 2 | 1951 Type 1 7.62mm pistol bullet (steel core) | 5.60g | 445±10 | 1954 7.62mm pistol |

| Grade 3 | 1951 Type 1 7.62mm pistol bullet (steel core) | 5.68g | 515±10 | Type 79 submachine gun |

| Grade 4 | 1956-style 7.62mm ordinary bullet (steel core) | 8.05g | 720±10 | 1956-style 7.62mm semi-automatic rifle |

| Grade 5 | 1953 type 7.62mm ordinary bullet (steel core) | 9.60g | 830±10 | 1979-style 7.62mm sniper rifle |

| Grade 6 | Type 53 armor-piercing incendiary | 10.45g | 810±10 | 1985-style 7.62mm sniper rifle |

| Note: The bulletproof performance over 6 is a special grade. |

According to the temperature of the environment where bulletproof transparent materials are used, they are divided into four levels, as follows:

| Level I | 0°C~40°C | Level III | -25°C~55°C |

| Level II | -10°C~55°C | Level IV | -55°C~85°C |

Code: The code of bulletproof transparent material is composed of product name code (FDCL), product classification code, product grade code, product thickness, enterprise custom code, and environmental suitability classification, for example: FDCL-2B-25-JF1-III

FDCL→ stands for bulletproof transparent material

2B → means level 2 splash resistance, that is, anti-1954 type 7.62mm pistol fired 1951 type 1 7.62mm pistol bullet (steel core)

25→The material is marked with a thickness of 25mm.

JF01→Enterprise custom code

III→Environmental temperature adaptability is Class III (-25°C~55°C)