Say Goodbye to Traditional Adhesives: Embrace the Efficiency of Hot Melt Glass

In today's fast-paced world, efficiency is key. We are constantly looking for ways to streamline processes and improve productivity. When it comes to adhesives, the traditional options have served us well for many years. However, there is a new player in town that is revolutionizing the industry - hot melt glass.

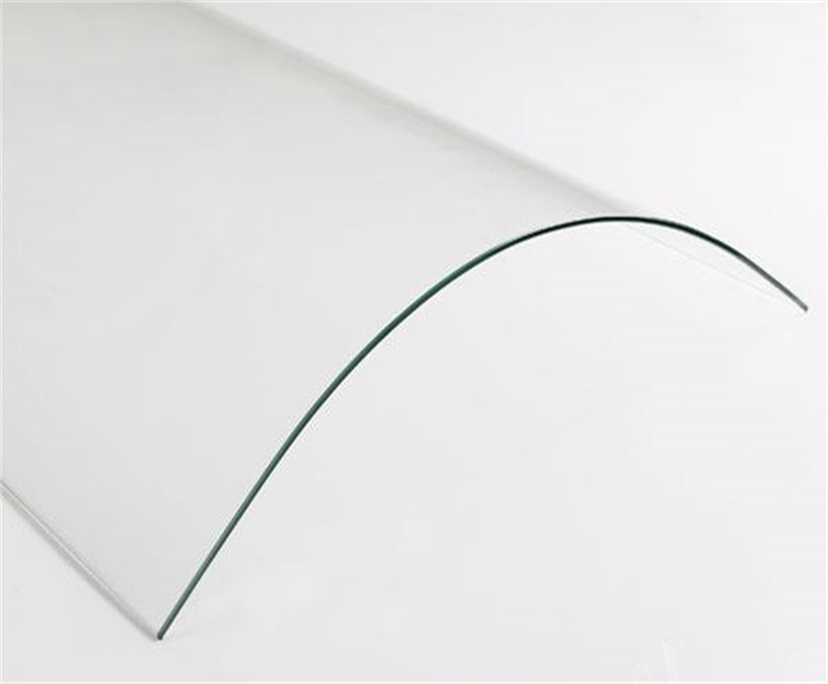

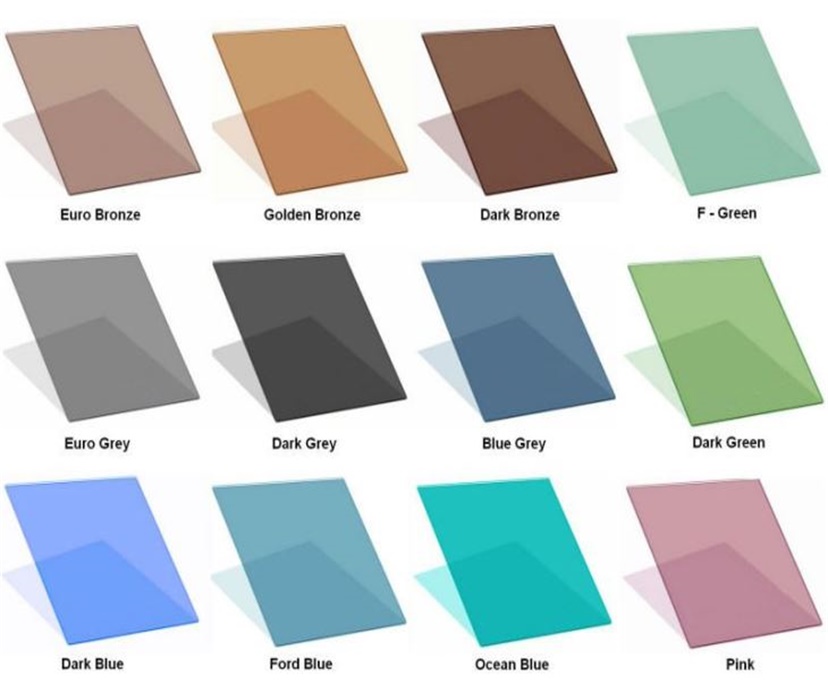

Hot melt glass is a cutting-edge adhesive solution that offers numerous advantages over traditional adhesives. It is a versatile material that can be used in a wide range of applications, from automotive manufacturing to electronics assembly. Its efficiency and effectiveness have made it a game-changer in the adhesive industry.

One of the key benefits of hot melt glass is its fast curing time. Unlike traditional adhesives that require hours or even days to fully cure, hot melt glass bonds within seconds. This rapid curing time significantly reduces production time and allows for faster assembly processes. Manufacturers can now complete projects at a much faster pace, increasing overall productivity and efficiency.

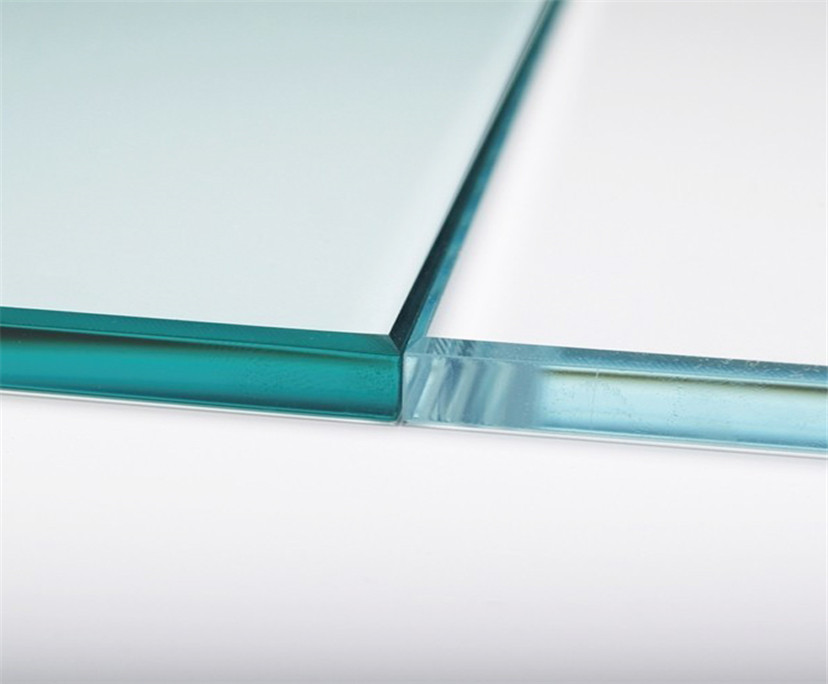

Another advantage of hot melt glass is its superior bonding strength. Traditional adhesives often struggle to provide strong and durable bonds, especially in challenging environments. Hot melt glass, on the other hand, forms a strong and reliable bond that can withstand extreme temperatures, moisture, and vibration. This makes it an ideal choice for industries where durability is crucial, such as aerospace and construction.

Hot melt glass also offers improved precision and accuracy. Traditional adhesives can be messy and difficult to control, leading to uneven application and wastage. Hot melt glass, however, is applied in a molten state and solidifies quickly upon contact, ensuring a precise and controlled application. This not only reduces material waste but also enhances the overall aesthetic of the finished product.

Furthermore, hot melt glass is environmentally friendly. Traditional adhesives often contain harmful chemicals that can be hazardous to both human health and the environment. In contrast, hot melt glass is free from volatile organic compounds (VOCs) and other toxic substances. Its eco-friendly nature makes it a sustainable choice for industries striving to reduce their environmental footprint.

The efficiency of hot melt glass extends beyond its application process. Its easy handling and storage make it a convenient choice for manufacturers. Unlike traditional adhesives that require special storage conditions or have a limited shelf life, hot melt glass can be stored at room temperature for an extended period without compromising its quality. This reduces the need for complex storage systems and minimizes the risk of adhesive wastage.

In conclusion, hot melt glass is a game-changer in the adhesive industry. Its fast curing time, superior bonding strength, precision, and eco-friendly nature make it a highly efficient choice for various applications. By embracing hot melt glass, manufacturers can say goodbye to the limitations and inefficiencies of traditional adhesives and embrace a new era of productivity and effectiveness. It's time to make the switch and experience the efficiency of hot melt glass.