Hot Melt Glass: The Game-Changer in Glass Bonding and Assembly

Glass has been a fundamental material in various industries for centuries, with applications ranging from architecture and automotive to electronics and packaging. However, the traditional methods of bonding and assembling glass components have often been time-consuming, labor-intensive, and limited in terms of strength and durability. Enter hot melt glass, a revolutionary technology that is set to change the game in glass bonding and assembly.

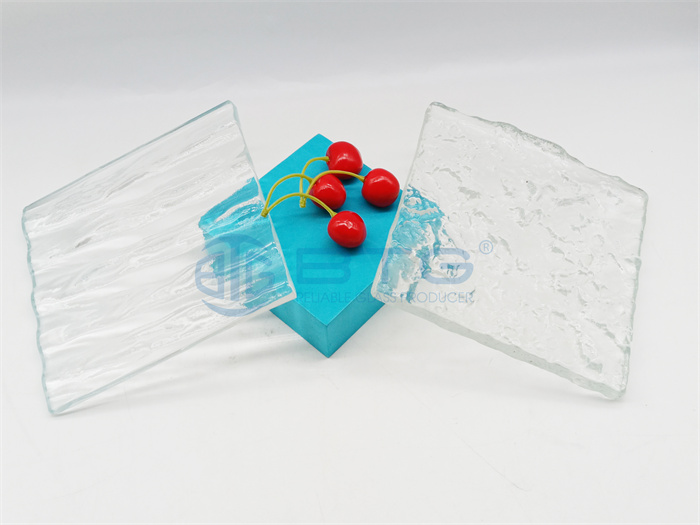

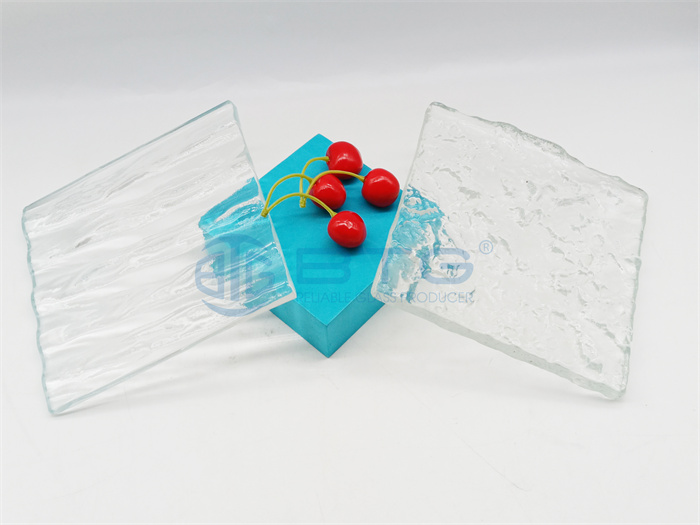

Hot melt glass, also known as thermoplastic glass, is a cutting-edge adhesive system that utilizes a specially formulated glass compound that melts at high temperatures and solidifies upon cooling. This unique characteristic allows for seamless bonding and assembly of glass components, eliminating the need for traditional methods such as welding, soldering, or using mechanical fasteners.

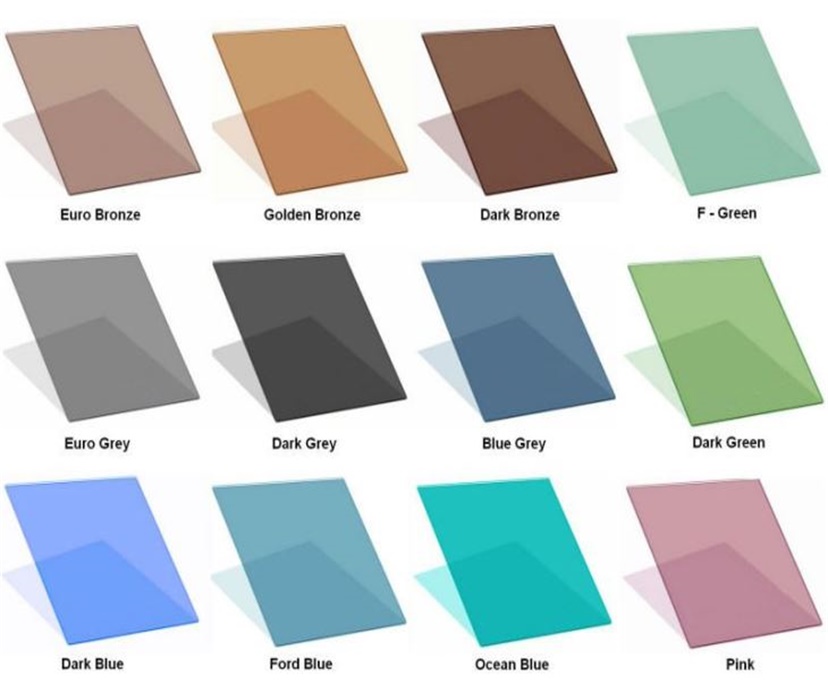

One of the key advantages of hot melt glass is its versatility. It can be used to bond different types of glass, including float glass, tempered glass, laminated glass, and even specialty glasses like borosilicate and quartz. This makes it an ideal solution for a wide range of industries, from automotive manufacturers looking to improve the strength and durability of windshields to electronics companies seeking efficient and reliable bonding of glass display panels.

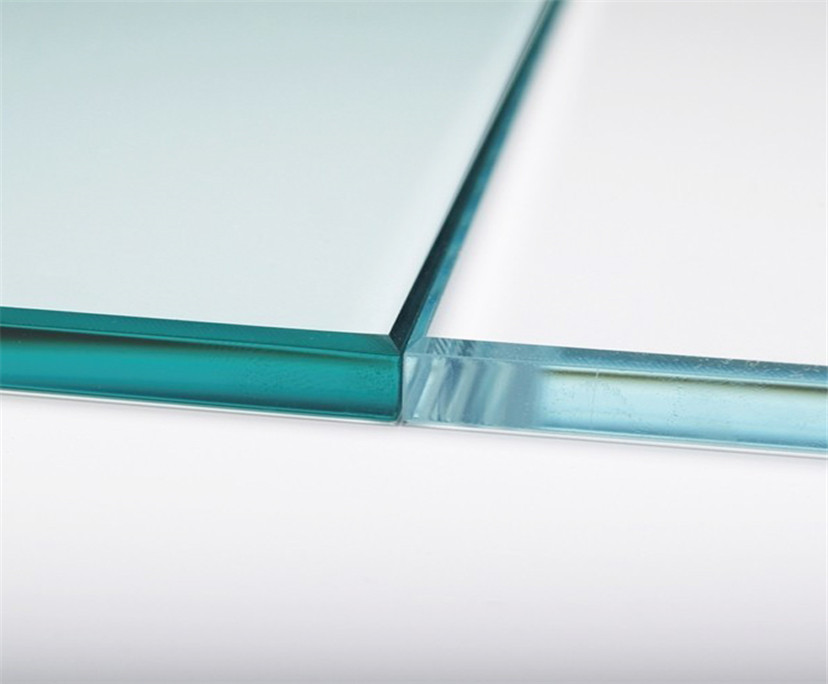

The process of using hot melt glass is straightforward and efficient. The adhesive is heated to its melting point and applied to the glass surfaces to be bonded. As it cools and solidifies, it forms a strong and durable bond, capable of withstanding various environmental conditions, including temperature fluctuations, moisture, and vibrations. This ensures the longevity and reliability of the bonded glass components.

In addition to its strength and durability, hot melt glass offers several other benefits. Unlike traditional adhesives, it does not require curing time or the use of additional chemicals. This significantly reduces production time and costs, making it an attractive option for manufacturers. Furthermore, hot melt glass creates a seamless bond without any visible seams or joints, enhancing the aesthetic appeal of glass products.

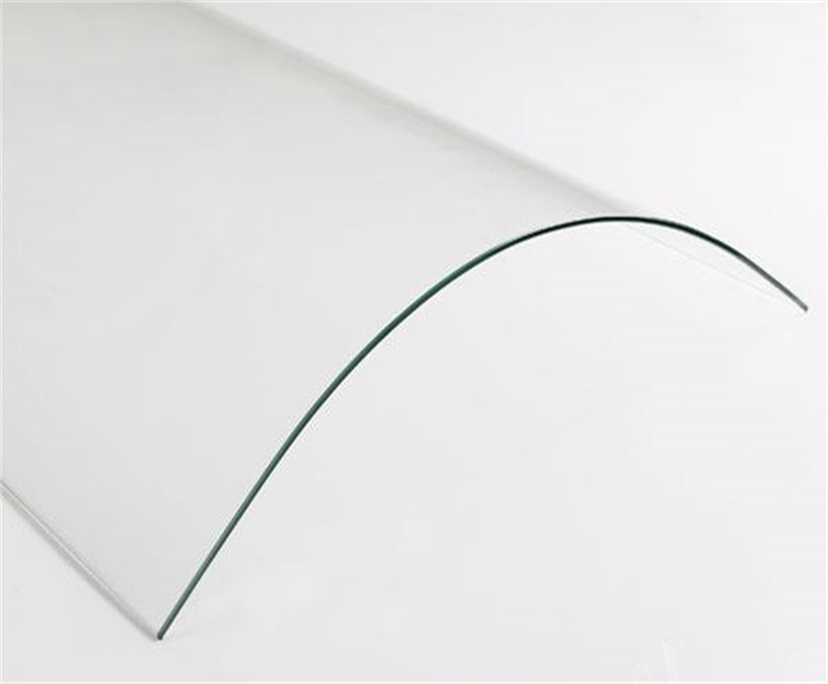

The applications of hot melt glass are vast and varied. In the automotive industry, it can be used for bonding windshields, sunroofs, and side windows, providing enhanced structural integrity and safety. In the construction sector, it offers a reliable solution for assembling glass facades, partitions, and decorative elements, enabling architects and designers to create stunning and functional spaces. Additionally, hot melt glass finds its use in electronics, where it ensures the precise bonding of glass display panels, touchscreens, and optical components.

As this groundbreaking technology continues to evolve, researchers and engineers are exploring new possibilities for hot melt glass. They are experimenting with different formulations to enhance its adhesive properties, increase its temperature resistance, and improve its compatibility with various types of glass. Furthermore, efforts are being made to develop automated systems for the application of hot melt glass, further streamlining the manufacturing process.

Hot melt glass is indeed a game-changer in glass bonding and assembly. Its strength, durability, versatility, and efficiency make it a superior alternative to traditional methods. As industries continue to embrace this technology, we can expect to see more innovative glass products and applications that were previously unimaginable. The future of glass bonding and assembly is here, and it's hot melt glass.