Laminated Glass Factory

Product Introduction:

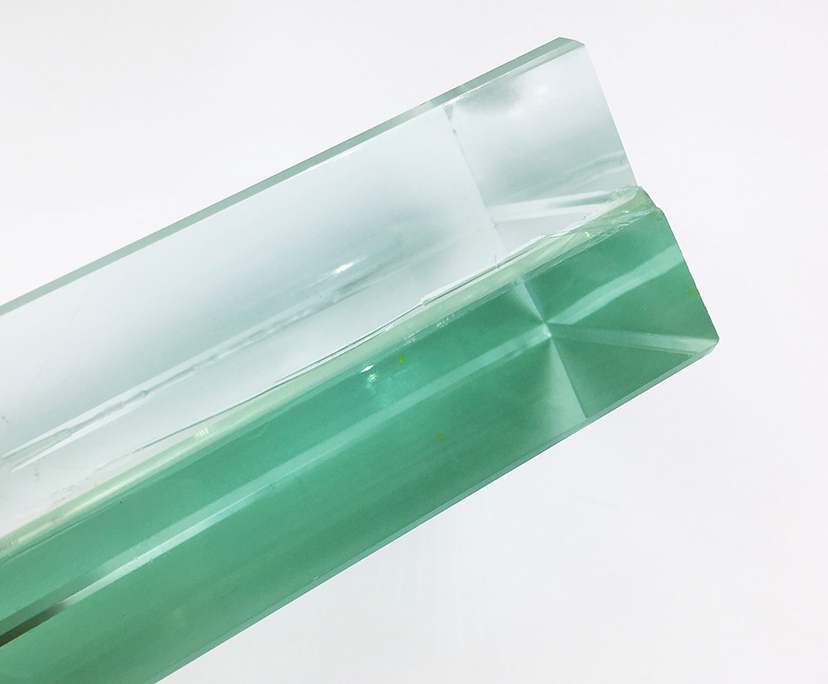

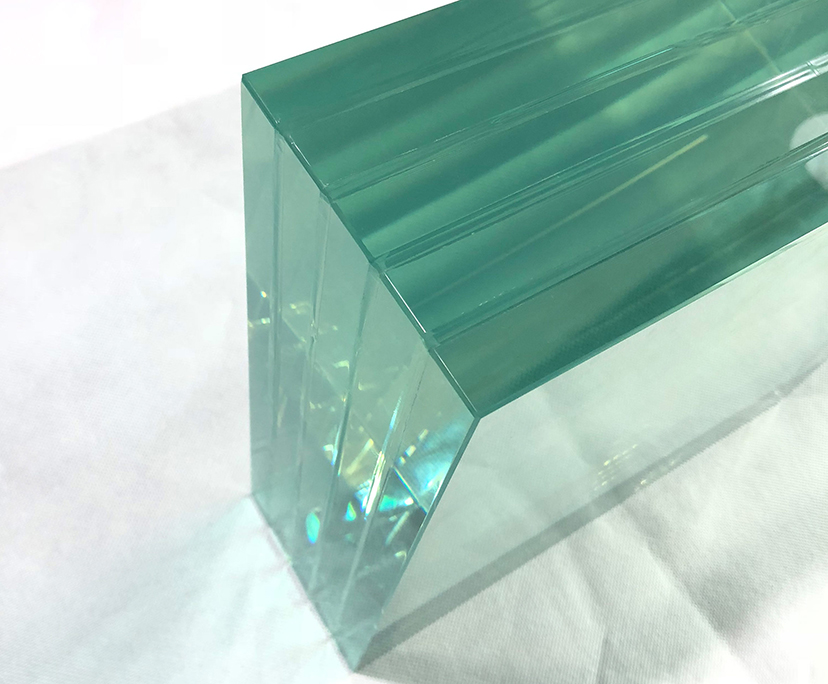

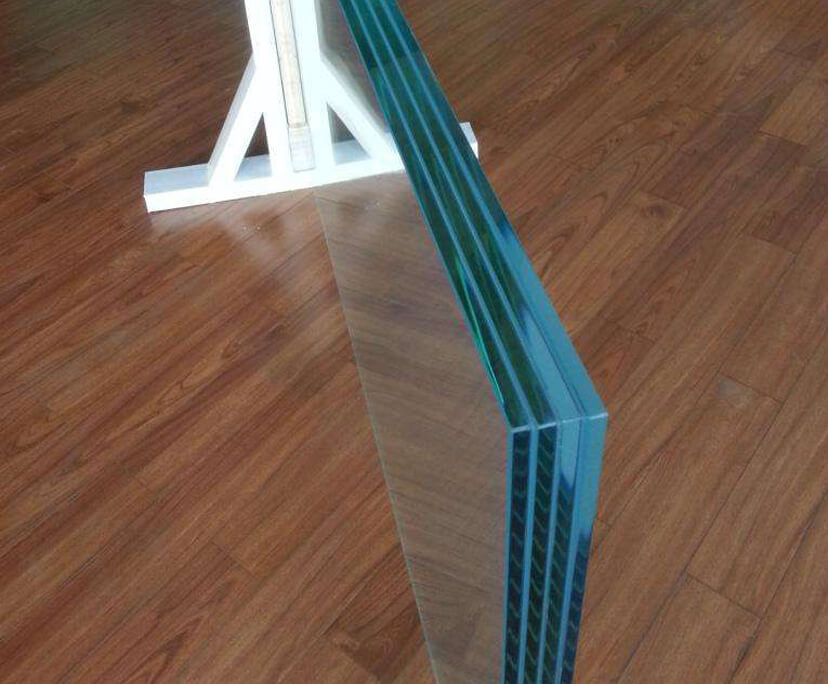

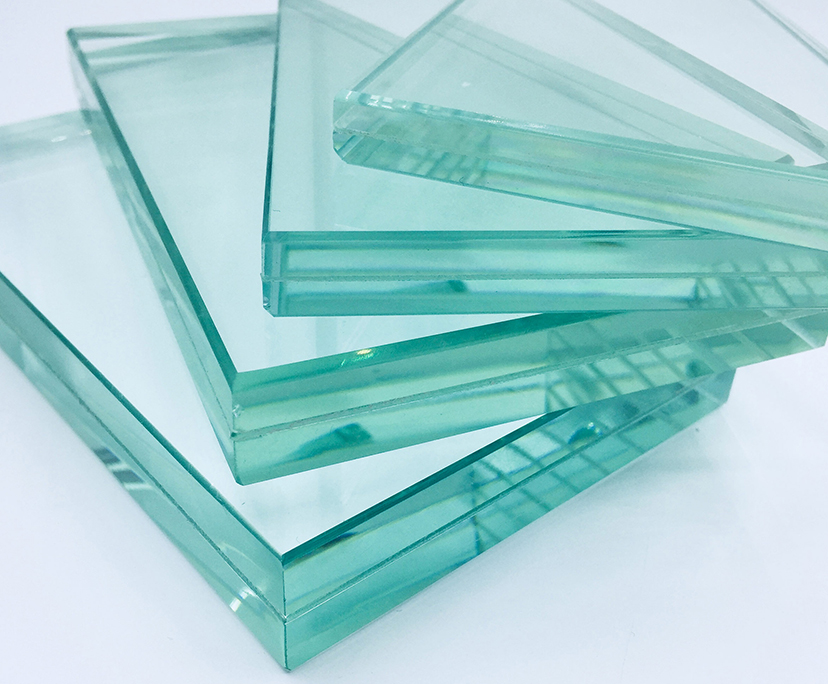

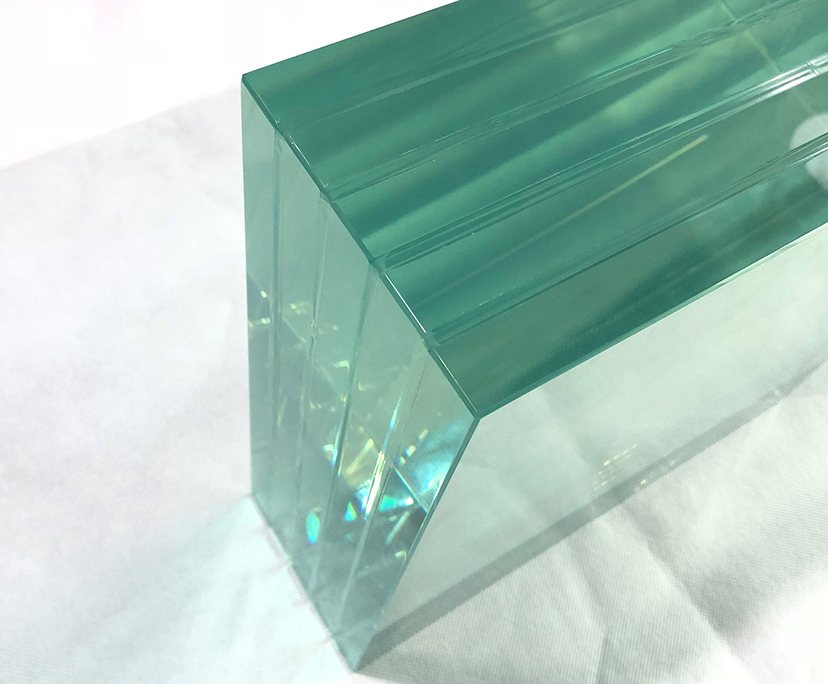

Laminated Glass is made of two or more pieces of glass which one layer or multi-layers of EVA/PVB/SGP with strong cohesion sandwiched under high temperature and pressure between them. The appearance and installation method of laminated glass sandwiched with transparent film are the same with normal glass, but much more durable.

PVB laminated glass is made by PVB sandwich film and tempered float glass.PVB is a kind of polymer material formed from polyvinyl butyral resin and plasticized by plasticizer 3GO (triethylene glycol diisooctanoate). The thickness of PVB glass interlayer film is generally 0.38mm and 0.76mm. It has good adhesion to inorganic glass and is characterized by transparency, heat resistance, cold resistance, moisture resistance, and high mechanical strength. PVB film is mainly used for laminated glass. It is a PVB film with polyvinyl butyral as the main component sandwiched between two glasses. PVB laminated glass is widely used in construction, automotive and other industries due to its many functions such as safety, heat preservation, noise control, and isolation of ultraviolet rays.

Product details

Characteristics

1. Safety

The tenacity of EVA/PVB/SGP which used for laminated glass is fairly good, It can quickly absorb and weaken a mass of striking energy when laminated glass is impacted by force, Therefore, laminated glass is hard to be penetrated and can remain integrally in the frame even when it is broken. Laminated glass is true safety glass.

2. Sound Insulation

EVA/PVB/SGP can effectively prevent sound wave, Sound wave can be obviously weakened when it goes through laminated glass, so that noise disturbance in office or living environment is reduced.

3. Anti-UV

Laminated glass can effectively prevent UV(more than 99% of UV) which can protect the valuable furniture, exibit and artwork etc. from discoloring caused by UV.

4. Anti-bullet and Anti-explosion

Multi-layer laminated glass can be made into various products of anti-bullet, anti-bombing and anti-explosion. Hurricane and earthquake resistance. Laminated glass has high persistent and strong cohesion enable the fragments remain in place, thus it’s suitable for hurricane and earthquake zone.

Applications

Due to its unique features. Laminated glass can be extensively used in building skylight, elevated floor, high grade curtain wall and window, furniture, showcase and aquarium etc.

EVA Laminated Glass

EVA is short for the Ethylene-Vinyl Acetate Copolymer, with water resistance, corrosion resistance. When the EVA film used in laminated glass, EVA melt temperature is low and fluidity is better relative to PVB or SGP. Difference in ordinary transmission and high transmission, Suitable for laminated something like folder roll, cloth, metal mess between the film. And can be made into patterns, materials, rich decorative glass. EVA is good for water resistance, but for the UV resistance is normal, when exposed under sunshine will prone to yellow aging. At present, EVA laminated glass is mainly used for indoor partition, shower room, etc. Generally for interior decoration.

Characteristics

1. Good for water resistance

2. Corrosion resistance.

Applications

Indoor partition, shower room, etc.

PVB Laminated Glass

PVB is also called as Polyvinyl Butyral, which is currently the most widely used interlayer material for architectural glass and automotive glass. PVB laminated glass has good safety, sound insulation and resistance to ultraviolet light, But PVB is not good for water resistance, a long term wet soak easy to delaminating. It has high transparency, good for cold resistance, impact resistance and UV radiation resistance.

Applications

PVB laminated glass can absorb the impact energy, doesn’t produce broken pieces, this safety glass is widely used in automobiles. Commercial buildings, bank counters, all kinds of bullet-proof glass. At the same time in the construction of curtain walls, recruiting, windows, bank counters, prison visits, steel stove screen and a variety of bullet-proof glass and other construction areas are also widely used.

Characteristics

1. Safety

The PVB laminated glass can prevent the penetration when the glass is broken by outside impact, because the layer can absorb the impact energy. Only produce crush cracks like spiderwebs, the glass debris firmly adhered to the middle layer, so it will not fall off and scattered, can continue to use and buy the time for replacement.

2. PVB laminated glass is very tough, even when the thieves break the glass, the glass will firmly together to keep the integrity because of the middle layer.

3. Sound Insulation

Because of the damping function of the acoustic wave, PVB laminated glass can be effectively reduce the spread of noise, especially in the airport, train station, downtown and road on both sides od the building. The sound insulation of our laminated glass is obvious.

4. Anti-Ultraviolet Performance

PVB film in the laminated glass can absorb more than 99% of the UV radiation, which can protect the indoor furniture, plastic products, textiles, carpets, artwork, ancient artifacts or goods from UV radiation. Can obviously avoid the fading and aging of those things.

5. Energy-Saving

PVB laminated glass can effectively reduce the sunlight through, we can use dark low light transmittance PVB film to make a laminated glass which can block the heat more powerful, At present, our company production of laminated glass with a variety of colors,

We can provide all kinds of color PVB according to the RAL code.

SGP laminated Glass also called as Sentry Glass Plus, which is one kind of high performance laminated materials developed by Dupont, Kuraray in the end of 2014 acquired.

SGP laminated glass has a very high strength, which can carrying the same thickness of the PVB sandwich bearing capacity of 2 times; the same time load and thickness of the case, SGP laminated glass bending deflection only 1/4 of the PVB laminated glass with the same thickness.

The SGP folder film tear strength is 5 times more than PVB folder film. Even when the SGP laminated glass is broken, the SGP film can also stick the broken glass breakage after the formation of a temporary structure, the bending deformation is small, but also can withstand a certain amount of load and not the whole piece of fall.

SGP film has a good edge stability, it's not sensitive to moisture. SGP folder film has colorless translucent and good weather resistance performance, not yellowing, The coefficient of SGP film is less than 1.5,while the PVB yellowing coefficient is 6-12,so its better when used for ultra clear laminated glass.

Applications

1. Glass barriers of public buildings, balcony doors and windows, indoor partition staircase between the glass and shield, a typical building airport terminal, glass roof, glass patio, tilt installation of the windows.

2. Floor,glass corridor, SGP laminated glass can withstand greater pressure and can meet the needs of transparent observation, can be used as submarine windows, deep water peep mirror, watch aquarium and so on.

3. High-rise buildings, large public buildings safety glass.

4. Pversized architectural glass, The use of SGP film production when more than 10meters in length od architectural glass or glass column, It’s safety can meet the needs of these architectural glass requirements.

- View More Glass

- Tempered Glass

- Hot Bending Glass

- SGP Laminated Glass

- Curved Glass

- Insulated Glass

- Low Iron Glass

- Reflective Glass

- Low-E Glass

- Frosted Glass

- Ceramic Glass

- Stairs Steps Glass

- Shower Glass

- Partition Glass

- Shop Front Glass

- U Glass

- LED Glass

- PDLC Switchable Glass

- Furniture Glass

- Appliance Glass

- Mirrors